Pipe lining is well worth the money, whether your pipes are damaged or not. Using pipe lining as a preventative measure is very popular because many piping is on the brink of corrosion or leakage. But you can also use it to repair a cracked pipe, so you don’t need to repipe your entire home.

Pipe lining is more than worth it as it can save the average homeowner up to 75% on plumbing and piping repair or replacement costs in the future. Repiping will likely cost homeowners more than pipe lining. And it will eventually have the same problems of corrosion and leakage.

What Is Pipe Lining?

Pipe lining is a material used to line the interior of piping in your home. It can work without digging or construction, and you don’t need to replace your pipes. Pipe lining essentially creates a brand new using the mold of the old one.

What Is Trenchless Pipe Lining?

Trenchless pipe lining is just a more specific name for pipe lining. People call it trenchless because you don’t need to dig into the ground to create trenches or perform any major construction on your property. Building trenches for water pipes was a method developed by the ancient Romans, but plumbing tactics have evolved to be more cost-effective and less intrusive on your property.

Purpose of Pipe Lining

The purpose of pipe lining is to offer a solution to corroded or leaking pipes in your home without installing a completely new pip system. It can be a preventative measure, especially in old homes. Old copper piping can’t last forever, and new technology is much more durable. It’s hard to renovate your pipework completely. Pipe lining prevents a more straightforward solution to old plumbing.

When to Use Pipe Lining

There is no wrong time to use pipe lining unless you just moved into a brand new, freshly built home. Almost all American homes, close to 80%, were built before 1945. Piping and plumbing have leaped lightyears forward since the mid 20th century, but most homes don’t reflect that progress.

Types of Pipe Lining

There are four main types of pipe lining in use today.

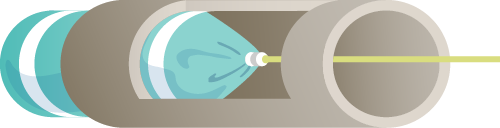

Cured-in Place

Contractors can install cured-in-place trenchless pipe lining without having to dig trenches or perform construction. The first step is to clean out and clear the damaged area of the pipe. They do this using flows of water and blasted air. Then, once it is clean and dry, they will apply the lining to the damaged area.

Once the lining reaches the correct area of the pipe, they use jets of hot steam to mold the lining into all the cracks inside.

Lining that cures in place is one of the most effective types of trenchless pipe lining when you experience a crack, leak, or damaged pipe in another way. Most people don’t use this type of lining as a preventative measure.

Read more – Does Trenchless Pipe Lining Work?

Pull-in-Place

Pull-in-place pipe lining requires two access points to the pipe but does not require an entire trench. So there is some digging, but much less. Pull in place is the best trenchless pipe lining for a pipe that has a massive crack or severe leak.

An epoxy-saturated material heats until pliable using steam jets, and then it is pulled into place directly over a critical crack. You need the two access points to feed the liner through one end and one to pull it through the other.

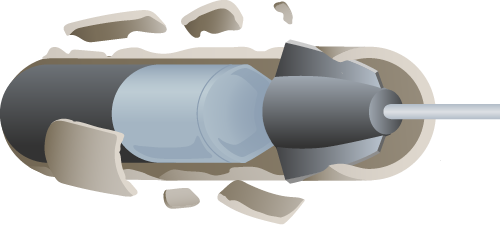

Pipe Bursting

Pipe bursting is a clever method of pipe lining. It destroys the old pipe while simultaneously laying a new one in its place.

You need access to the pipe itself for this, so two holes must be dug on either end. But this is still far less disruptive than digging a whole trench to expose an entire pipe.

The process begins with the holes, and then, on one end of the pipe, you place a bursting head that will push through. As the hydraulic pressure pushes the head through, it breaks the old pipe while lining the area with a new one.

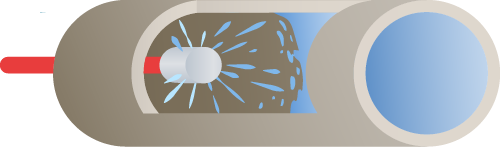

Internal Pipe Coating

Internal pipe coating is excellent for both repairs and preventative maintenance. Internal pipe coating is ideal for preventing sewage from leaking out and contaminating surrounding soil. To prepare piping for this treatment, they must remove any water from the pipe.

Then, they spray a super thick epoxy coating on the interior of the pipes, aiming at any leaks, cracks, or weak points.

Pros and Cons of Trenchless Pipe Lining

Trenchless pipe lining is worth it, but show you how great it is, look at how the pros and cons balance out.

Pros

Here are the best upsides to using pipe lining. These are the top reasons to install it, but there are many more.

Efficient

The installation process of pipe lining is much faster and easier than a new pipe. Pipe lining installation takes a short amount of time, so you don’t have to put your comfortable home life on hold for weeks while construction surrounds you.

Environmentally-Friendly

Compared with metal piping and the amount of material needed, pipe lining is super eco-friendly. It uses little waste and is much less intrusive on the environment.

No Trenches

The best part of trenchless pipe lining is the lack of digging! If you’ve ever dealt with repiping, you know what an absolute nightmare the construction can be, so pipe lining is a lifesaver.

Cons

Here is the only real downside to using trenchless pipelines to consider.

Sometimes Impossible

The major downside of trenchless pipe linge is that it just isn’t possible sometimes. If a pipe is irreparably damaged, the only option is to replace it, and unfortunately, that means digging a trench.

Bottom Line

Pipe lining is worth it, whether you have an old house, cracked pipes, or want to get ahead of any problems. All types of pipe lining leave a smooth sealed coating that is guaranteed to last decades. So don’t wait to call professionals to make your pipes as good as new.