Seamless Solutions for Your Pipeline Needs – Safe, Efficient, and Zero Downtime!

Long-Term Reliability: Expert Hot Tap Pipeline services provide a secure, durable connection to your pipeline, ensuring seamless operation and preventing future disruptions or costly repairs.

Enhanced System Efficiency: Professionals ensure precise tapping and installation, maintaining optimal flow and functionality without interrupting your pipeline’s operation.

Safe and Effective Techniques: Skilled technicians utilize advanced tools and methods to perform hot tapping safely and accurately, protecting the integrity of your pipeline and minimizing risks.

Schedule Service in 3 minutes | No Credit Card Required | Enjoy Fast, Hassle-free Solution

Don’t Let High Prices Tap You Out – Save Big on Hot Tapping!

Don’t let pipeline disruptions slow you down—choose our expert Hot Tap Pipeline services for fast, reliable solutions that keep your operations flowing seamlessly!

Tapping Pipes, Keeping the Flow—Safe, Precise, and Ready to Go!

Monica M. | Homeowner

Nick & his team were very responsive in resolving my issue. I appreciate the consistent communication throughout the process and great customer service!

Schedule Service Online

Easy as 1-2-3

Our Reputation is Tapped in!

Hot Tap Pipeline Services

A hot tap is a procedure used to create a new branch connection on a live, pressurized pipeline without shutting down the flow of the substance inside, whether it’s gas, oil, water, or other fluids. This method involves drilling into the pipeline while it remains operational, using specialized equipment that allows for safe cutting and attachment of a new connection. Hot tapping is essential for maintenance, repairs, or expanding pipeline networks without disrupting service, making it a critical technique in industries where continuous operation is vital.

What You Need to Know About Hot Tapping Services

Hot tapping, also known as pipeline hot tapping, is a highly specialized technique used in various industries such as oil, gas, water, and chemicals to create a new connection or perform modifications on an existing, live pipeline without interrupting the flow within the pipe. This process is essential for maintaining continuous operation, which is particularly crucial in industries where shutting down a pipeline can result in significant financial losses or pose safety risks.

What is Hot Tapping?

Hot tapping is the process of drilling into a pressurized pipeline while it is still in service. The technique allows for the installation of a branch connection, valve, or other components to the pipeline without having to stop the flow of the substance being transported. This is achieved using specialized equipment that safely cuts into the pipeline and attaches the new connection in a controlled and secure manner.

How Pipeline-Hot-Tapping Services Work

Hot-tap pipeline services involve several steps to ensure the procedure is carried out safely and effectively:

Site Preparation: Before the hot tap, the pipeline section where the tap will occur is thoroughly inspected to ensure it is in good condition and can handle the stress of the operation.

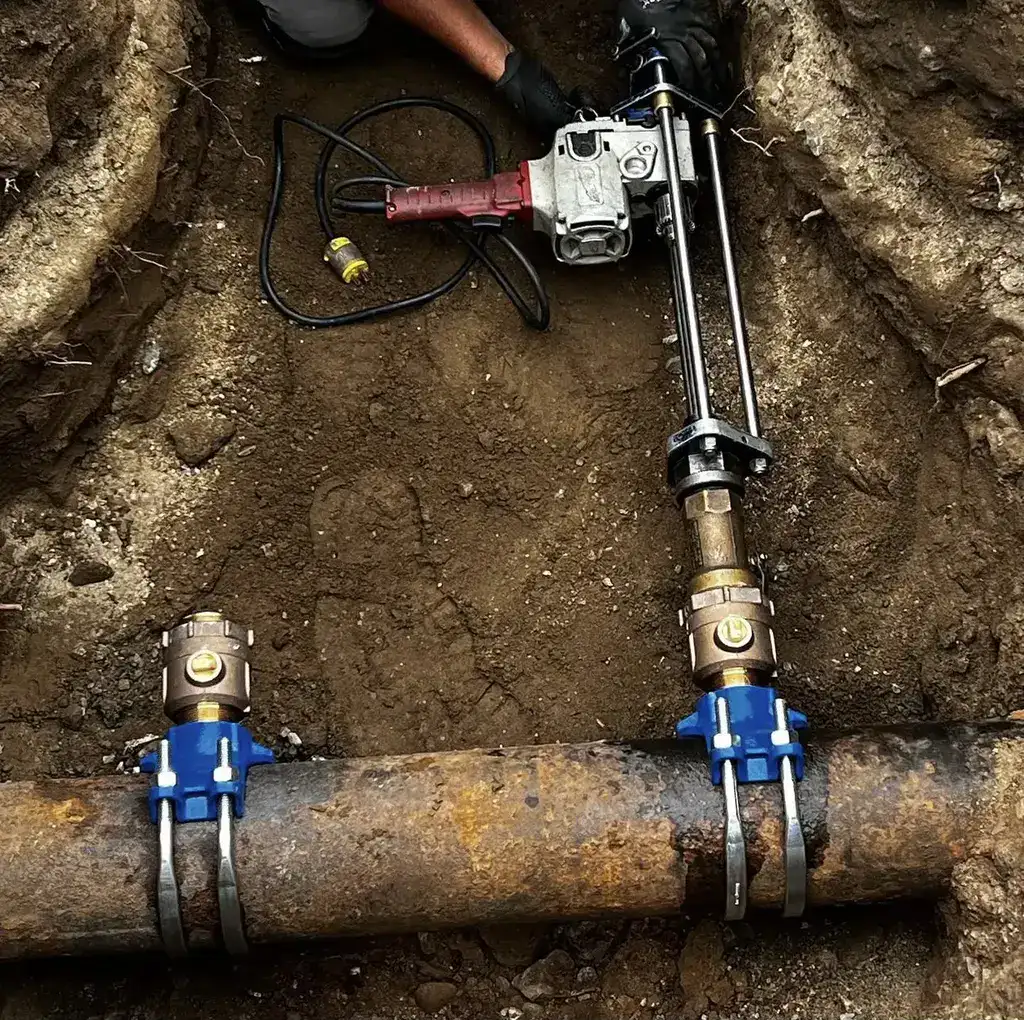

Fitting Installation: A fitting, usually a welded or mechanical fitting, is installed onto the pipeline. This fitting serves as the point where the hot tap machine will attach.

Hot-Tap Machine Setup: The hot-tap-machine, which includes a cutting tool and a sealing mechanism, is then attached to the fitting. This machine is designed to drill into the pipeline without releasing the pressurized contents.

Drilling Process: The cutting tool is advanced into the pipeline, creating an opening for the new branch connection. During this process, the machine ensures that no product escapes from the pipeline, maintaining the integrity of the operation.

Completion: Once the cut is made, the new branch connection is installed, and the hot tap machine is removed. The pipeline continues to operate normally throughout the process.

Applications of Hot-Tapping Services

Hot tapping is used in various scenarios, including:

- Pipeline Extensions: Adding new branches or connections to an existing pipeline network.

- Maintenance: Performing repairs or installing new equipment on a live pipeline without shutting it down.

- Emergency Response: Implementing quick solutions in situations where shutting down a pipeline could be dangerous or costly.

Safety Considerations

Pipeline hot tapping requires a high level of expertise and adherence to safety protocols to prevent accidents, such as leaks, explosions, or environmental damage. The procedure must be conducted by trained professionals using certified equipment to minimize risks. Proper assessment of the pipeline’s condition, pressure, and the nature of the contents is crucial before proceeding with the operation.

Advantages of Hot-Tap Services

- Continuous Operation: The primary advantage of hot tapping is the ability to maintain pipeline operation without interruption, avoiding costly shutdowns.

- Flexibility: Hot tapping allows for on-the-fly modifications, repairs, or expansions of pipeline networks, making it highly versatile.

- Cost-Efficiency: By eliminating the need to shut down the pipeline, hot taps reduces downtime and associated costs.

In summary, hot tapping services are a vital component of modern pipeline management, enabling operators to modify, repair, or extend pipeline systems without halting the flow of product. This technique, while requiring specialized skills and equipment, offers significant benefits in terms of operational continuity, safety, and cost-effectiveness.

The Pros and Cons

Hot-tap pipeline work, is a critical technique used in industries like oil, gas, water, and chemicals to make modifications or repairs to live pipelines without shutting down operations. This specialized process, provided by hot tapping pipeline services, allows for drilling into a pressurized pipeline to create a new connection or branch, ensuring continuous service. While hot taps offers many advantages, it also comes with certain challenges. Below, we explore the pros and cons of hot tapping pipeline work.

Pros of Hot-Tapping Pipeline Work

Continuous Operation: One of the most significant advantages of hot tapping pipeline work is that it allows pipelines to remain in operation while modifications or repairs are made. This means no interruption in service, which is crucial for industries where downtime can lead to substantial financial losses or safety concerns.

Cost-Efficiency: Hot tapping services are cost-effective because they eliminate the need to shut down the entire pipeline system. This reduction in downtime minimizes revenue loss and avoids the high costs associated with stopping and restarting pipeline operations.

Flexibility and Versatility: Hot tapping provides a flexible solution for pipeline modifications, whether for adding new branches, performing repairs, or installing monitoring equipment. It can be applied to various pipeline systems, making it a versatile tool in pipeline management.

Safety During Emergencies: In emergency situations, hot tapping can be a critical method for making quick repairs or modifications without the need to depressurize the system, thus maintaining safety and continuity.

Cons of Hot Tapping Pipeline Work

High Skill Requirement: Hot tapping is a complex process that requires highly skilled professionals to execute safely. The procedure involves drilling into a live, pressurized pipeline, and any mistake can lead to serious accidents, including leaks or explosions.

Specialized Equipment Needed: Performing a hot-tap requires specialized equipment designed to handle the pressures and temperatures involved in the process. This equipment must be carefully maintained and operated, adding to the cost and complexity of the procedure.

Limited Pipeline Condition Suitability: Not all pipelines are suitable for hot tapping. The pipeline’s condition, including its age, material, and the nature of the contents, must be carefully assessed before proceeding. If the pipeline is too old or damaged, hot tapping may not be feasible, and alternative methods must be considered.

Risk of Accidents: Despite the safety measures in place, hot tapping inherently involves risks. The process of drilling into a pressurized system carries the potential for accidents, making thorough planning, risk assessment, and adherence to safety protocols essential.

In summary, hot tapping pipeline work offers significant benefits, particularly in terms of maintaining continuous operation and cost-efficiency. However, it also presents challenges, including the need for specialized skills, equipment, and careful risk management. For industries where downtime is not an option, hot tap pipeline services provide a vital solution, but it is crucial to weigh the pros and cons to ensure the procedure is appropriate for the specific pipeline system and situation.

Hot tapping pipeline work, is a critical technique used in industries like oil, gas, water, and chemicals to make modifications or repairs to live pipelines without shutting down operations. This specialized process, allows for drilling into a pressurized pipeline to create a new connection or branch, ensuring continuous service. While hot taps offers many advantages, it also comes with certain challenges. Below, we explore the pros and cons of hot tapping pipeline work.

Pros of Hot-Tapping Pipeline Work

Continuous Operation: One of the most significant advantages of hot tapping pipeline work is that it allows pipelines to remain in operation while modifications or repairs are made. This means no interruption in service, which is crucial for industries where downtime can lead to substantial financial losses or safety concerns.

Cost-Efficiency: Hot tapping services are cost-effective because they eliminate the need to shut down the entire pipeline system. This reduction in downtime minimizes revenue loss and avoids the high costs associated with stopping and restarting pipeline operations.

Flexibility and Versatility: Hot tapping provides a flexible solution for pipeline modifications, whether for adding new branches, performing repairs, or installing monitoring equipment. It can be applied to various pipeline systems, making it a versatile tool in pipeline management.

Safety During Emergencies: In emergency situations, hot tapping can be a critical method for making quick repairs or modifications without the need to depressurize the system, thus maintaining safety and continuity.

Cons of Hot Tapping Pipeline Work

High Skill Requirement: Hot tapping is a complex process that requires highly skilled professionals to execute safely. The procedure involves drilling into a live, pressurized pipeline, and any mistake can lead to serious accidents, including leaks or explosions.

Specialized Equipment Needed: Performing a hot tap requires specialized equipment designed to handle the pressures and temperatures involved in the process. This equipment must be carefully maintained and operated, adding to the cost and complexity of the procedure.

Limited Pipeline Condition Suitability: Not all pipelines are suitable for hot tapping. The pipeline’s condition, including its age, material, and the nature of the contents, must be carefully assessed before proceeding. If the pipeline is too old or damaged, hot tapping may not be feasible, and alternative methods must be considered.

Risk of Accidents: Despite the safety measures in place, hot tapping inherently involves risks. The process of drilling into a pressurized system carries the potential for accidents, making thorough planning, risk assessment, and adherence to safety protocols essential.

In summary, hot tapping pipeline work offers significant benefits, particularly in terms of maintaining continuous operation and cost-efficiency. However, it also presents challenges, including the need for specialized skills, equipment, and careful risk management. For industries where downtime is not an option, hot tap pipeline services provide a vital solution, but it is crucial to weigh the pros and cons to ensure the procedure is appropriate for the specific pipeline system and situation.

Ensuring Seamless Operations in Complex Piping Systems: Hot-Tapping Procedure

The hot-tapping procedure involves multiple stages to ensure optimal safety and efficiency. The process starts with the selection of the appropriate tapping machine and cutter, based on specifications such as pipe diameter, material, and operating temperature. Typically, this technology is used on various pipe materials, including steel, cast iron, and carbon steel, each requiring specific cutter types.

Once the tapping machine is properly secured to the pipe section with fittings and valves, technicians execute the drilling using a drill motor to penetrate the pipe wall. During this process, maintaining pressure integrity is crucial to ensure that there are no leaks. High-quality seals, plugs, and reinforcement are used to prevent leaks and provide additional protection.

The technicians involved in the tap procedure must have advanced training, as even a minor miscalculation can lead to issues or safety hazards. By adhering to strict regulations and industry standards, experts ensure that the pipe plug remains effective, the procedure meets performance requirements, and the hot-tap complies with all relevant codes.

Hot-Tap Pipeline Capabilities

The success of a hot tap project relies on the capability and experience of the technicians and the quality of the products used. The entire hot tap procedure is designed to ensure there is minimal disruption, adherence to safety protocols, and compliance with regulations. Key elements in achieving a successful hot tap include:

Welding and Material Compatibility: The welding process involved in attaching a fitting to the existing pipe requires careful material selection. For example, the material used for welding fittings onto carbon steel pipes should match the requirements of the piping system to ensure compliance and durability.

Pipeline Maintenance and Testing: After the hot tap, thorough testing is conducted to confirm that the fitting and new connection meet the specifications. This involves pressure testing the taps and valves for quality assurance.

Line Stopping and Isolation: In scenarios where sections of a pipeline need to be isolated, line stopping is utilized in combination with hot tapping. This helps in isolating parts of the piping for repairs or maintenance while keeping the remainder of the pipeline in operation.

Corrosion Protection and Hazards: In the pipeline industry, addressing corrosion is essential for maintaining quality and safety. After the completion of the hot tap, protective coatings are applied to ensure the new section resists corrosion and that any new connections do not compromise the overall integrity of the piping system.

Compliance and Quality Assurance: Compliance with industry standards and regulations is a priority throughout the hot tap procedure. By meeting these specifications, the integrity of the piping system is preserved, and the quality of field services is ensured.

Applications and Industry Needs

Hot tapping is versatile, with applications in water distribution, sewage systems, oil and gas pipelines, and other infrastructure projects. It allows for piping improvement without the need for complete shutdowns, making it a preferred solution in situations where continuity is paramount.

Hot tap pipeline services are especially valuable in industries handling hazardous materials or dealing with high-pressure environments, where interruptions to the flow could lead to safety risks, production losses, or costly downtimes. The pipeline tapping process effectively addresses these challenges while preserving the performance of the piping systems.

Choosing the Right Team

The execution of a hot tap pipeline project requires a team of skilled experts who understand the intricacies of pipeline tapping, line stopping, and other related procedures. Proper knowledge of pipe specifications, including pressure ratings, sizes, and materials, is crucial to meet project needs. Skilled technicians, who have undergone comprehensive training, play a significant role in the safe execution of these processes.

The selection of tapping machines, plugs, valves, and reinforcement products also significantly impacts the outcome. Whether the project involves working with large-diameter pipes or small pipelines, the knowledge and expertise of technicians ensure that the right approach is used for each unique requirement.

Requesting Hot-Tap Services

When seeking hot tap pipeline services, it is important to get a quote that factors in the type of materials, pipe sizes, welding requirements, and line stopping capabilities. This ensures that the project is scoped accurately and any potential issues are addressed ahead of time. Companies offering these services need to demonstrate proficiency in compliance with relevant industry codes, in addition to having quality equipment and trained technicians.

Hot tap services add value to the maintenance and expansion of pipeline systems while offering a solution that aligns with environmental, operational, and regulatory considerations. Whether working on steel or cast iron piping, these procedures provide a reliable method for executing pipeline modifications and improvements without unnecessary risks or interruptions.

In conclusion, hot tapping represents a significant advancement in the field of pipeline maintenance and modification. By utilizing the latest technologies, tapping machines, and tapping procedures, companies can improve infrastructure, enhance distribution, and ensure the safe execution of pipeline projects. These field services provide long-term value, minimizing the impact on existing operations while enhancing the overall performance of piping systems.

Partnering With True Professionals

Given the complexity and potential hazards associated with Hot Tapping Pipelines, working with experienced professionals is often the best approach. We specialize in these services and can provide expert guidance, skilled crews, and the necessary equipment to complete the project efficiently and safely.

Hot tapping is a multifaceted task requiring careful planning, quality materials, and skilled execution. By understanding the components, factors, and best practices, you can ensure successful and durable repairs for your building or project. We use the latest hot tapping technologies. Our skilled technicians are equipped with the right tools and knowledge to tackle any plumbing problems. SWE Sewer Solutions Construction and Engineering offers these types of plumbing services.

We provide both homeowners and businesses with 24/7 emergency services to serve you during those difficult times when many other plumbers are closed. We are a bonded sewer contractor, servicing the Southern California area since 1980. Our expert technicians are trained and certified to complete any hot-tapping service.

We are a family-owned and operated company providing both residential and commercial sewer services. We look forward to delivering the best customer service care. You can rest assured that any warranties on your equipment will remain valid for the life of the warranty. When life throws a wrench in your plumbing, we’ll fix it. For more information, quotes, or to schedule an appointment, call us at 888-54-SEWER (888-294-1229) or visit our contact page today.